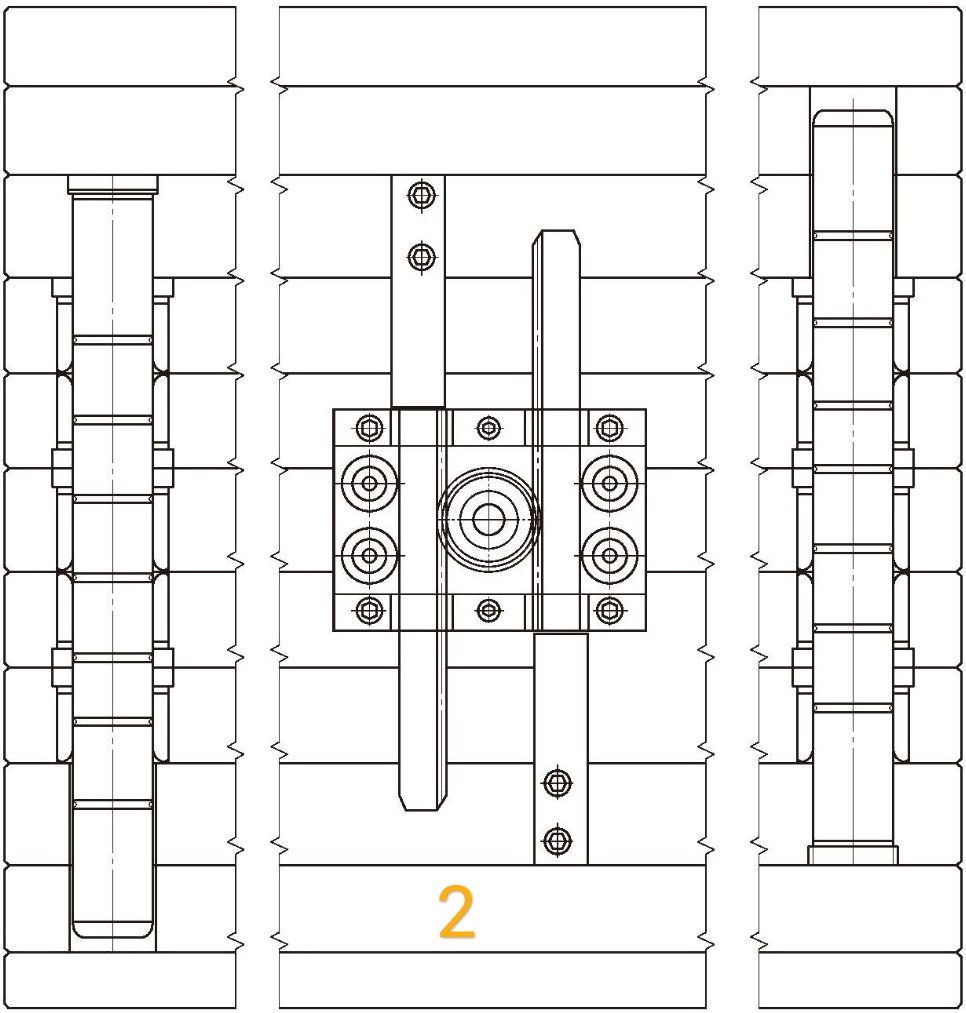

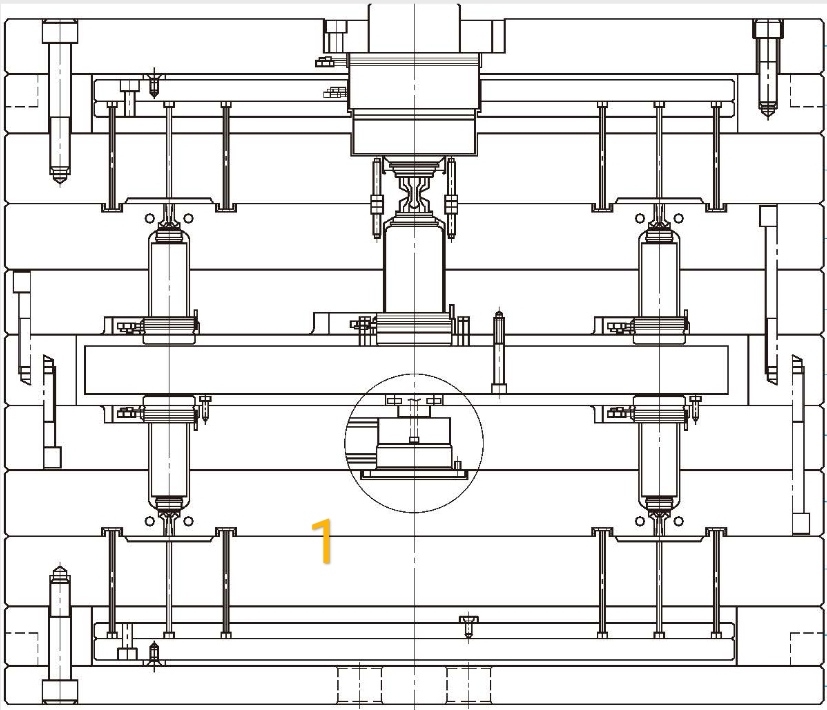

According to our experience on the hot runner system, the most difficult part for designing a hot runner stacked mold is the feed system, for doing the system, we need to do the injection on two stacks at the same time. To continue to complete the system, we need to do the hot runner system on the middle cavity plate, while the middle cavity, cavity, core have to be separated, so the main material nozzle should be split into detachable parts as shown in Figure 1.

Design specifications:

1. The part of the main material nozzle should not have a cold slug, so we use the shut-off nozzle for two main material nozzles.

2. Since the molded product remains on the cavity side and the core side, both cavity, and core should have an ejection system to facilitate the operator's removal of the product during automated production.

To ensure that the cavity and core are ejected synchro, both cavity and core should use hydraulic ejection.

If you don't need to synchronize the action, then the cavity can work on the hydraulic ejection, and the core can utilize knock-out ejection.

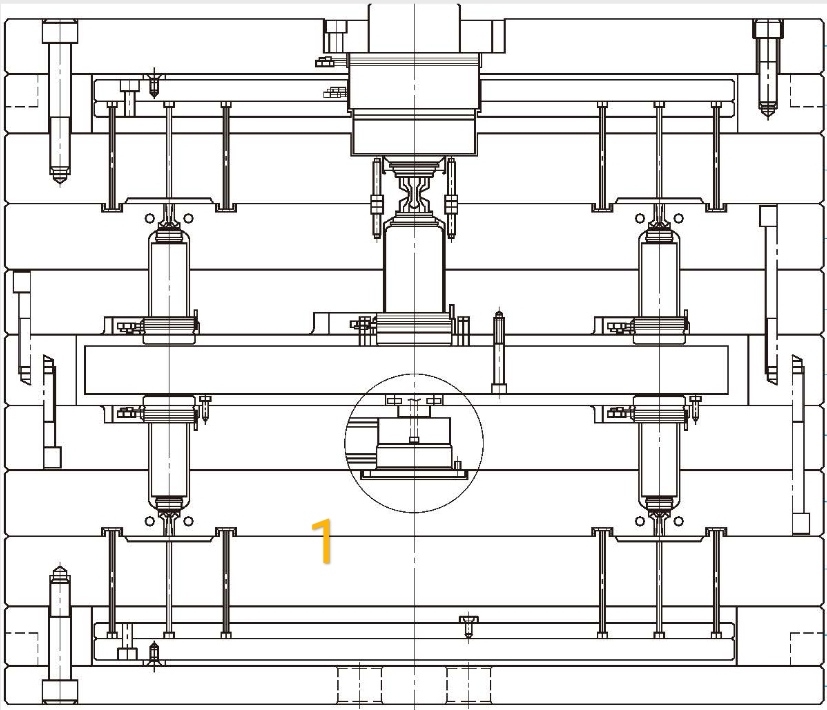

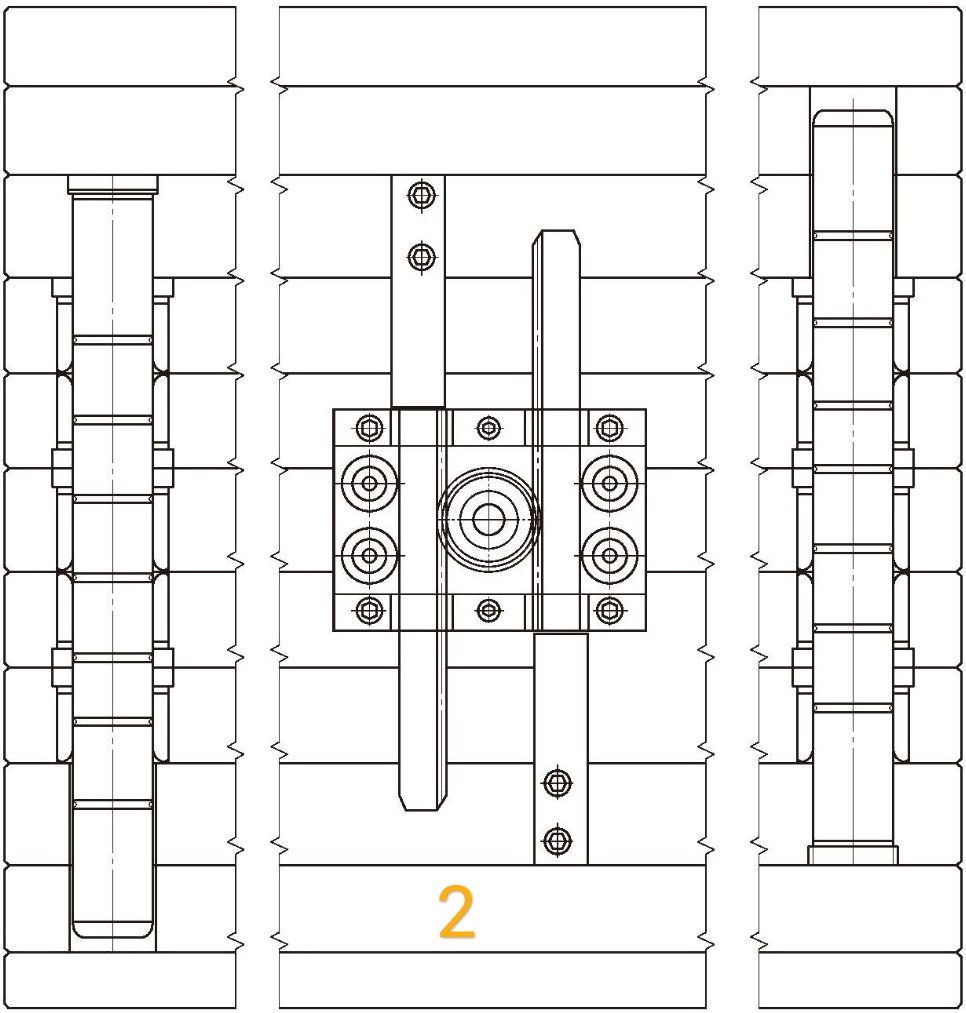

3. If the mold is large, the mold frame size exceeds 5050, in order to ensure the stability of the mold, the cavity and core should do the guide pin as shown in Figure 2.

4. In order to ensure that both sides of the parting surface open at the same time, and the middle cavity on both sides of the open mold distance is equivalent, the mold should use the gear and rack driving mode, so that the two sides of the opening mode synchronization and the opening distance is equivalent, as shown in Figure 2.

5. The opening distance of the parting surface on both sides of the mold can take out the product, therefore, the design should be designed along with upper mold limit and stroke switch, to prevent die sinking distance too long, in a fully open mode state, the rack and gears should not be separated.

6. There should be positioned between the two middle cavity plates and the hot runner plate for easy installation of the hot runner system.