When the mold insert's partial part has a more and deeper plastic material, after completing the plastic injection, the product has a heavy packaging force on the insert, which will lead to a bad result that the deeper part of the product has packaged mold tightly, it makes trouble to eject mold by producing ejector mark, ejector scratch, resulting in an abnormal production issue.

To resolve the problem, we make the partial part to be an active insert, before opening the mold or ejection, pulling the part firstly.

As shown in figure 1, the structure of the product is easy, but the 4 bosses' depth is too deeper and the 4 bosses are ejected on the cavity side. If we open the mold directly, the 4 bosses will be sticking the cavity, so we consider pulling the insert at the 4 bosses out, then we open the mold.

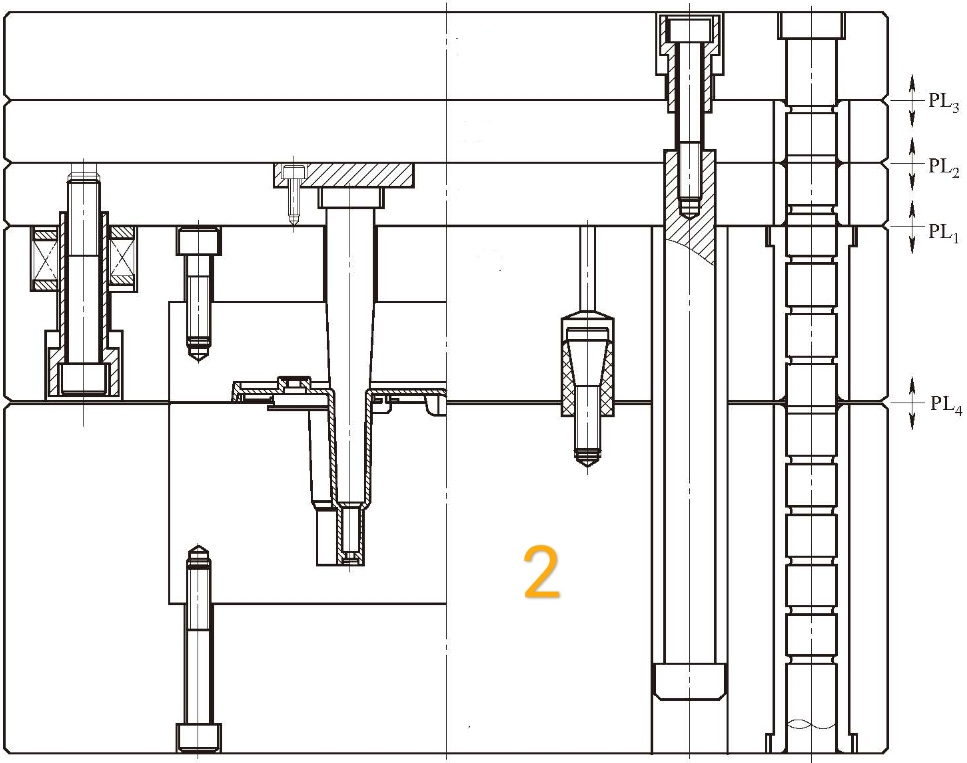

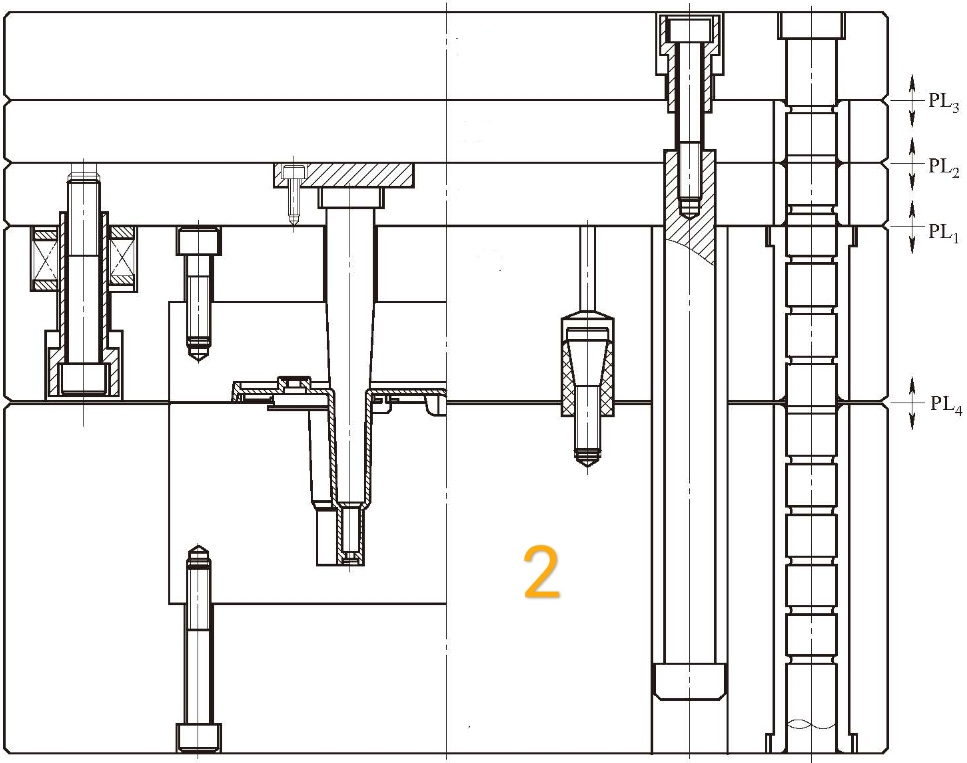

As shown in figure 2, generally, there are two ways of designing the pin-point gate cavity core-pulling system. One way is to get a priority core-pulling plate involved, and fix the priority core-pulling insert on the priority core-pulling plate; the other way is to fix the insert on the top clamp plate.

Whether you need a priority core-pulling plate is decided by the real situation.

Situation 1, you don't need the priority core-pulling plate if fixing the insert on the plate won't affect the mold's structure and design.

Situation 2, you have to add a priority core-pulling plate to the designation first if fixing the insert on the plate will have effects on the mold's structure like the runner or other components.

Design specifications:

1. If the system is without a priority core-pulling plate, design it as the normal pin-point gate, just need to fasten the priority pulling insert on the top clamp plate.

2. If the system has the priority core-pulling plate, do the limit between the priority core-pulling plate and plate A, and the limit stroke is equal to the priority pulling distance.

3. If the system involves the priority core-pulling plate, the force of the latch should be directly on the priority core-pulling plate, and when designing the latch stroke, the surface of the priority core-pulling plate should be used as the datum.

4. Mold opening order is to open PL1 and PL2, then open PL3, and finally open PL4. Although, for PL1, there is a spring-assisted open mold because the product to insert has a larger packing force, so not sure will be able to open first, and ultimately must rely on the latch to pull this position. Therefore, PL1 and PL2 in no order of opening the mold, no matter where to open first can be, the mold action and structure has no impact.

As shown in figure 2, generally, there are two ways of designing the pin-point gate cavity core-pulling system. One way is to get a priority core-pulling plate involved, and fix the priority core-pulling insert on the priority core-pulling plate; the other way is to fix the insert on the top clamp plate.

As shown in figure 2, generally, there are two ways of designing the pin-point gate cavity core-pulling system. One way is to get a priority core-pulling plate involved, and fix the priority core-pulling insert on the priority core-pulling plate; the other way is to fix the insert on the top clamp plate.