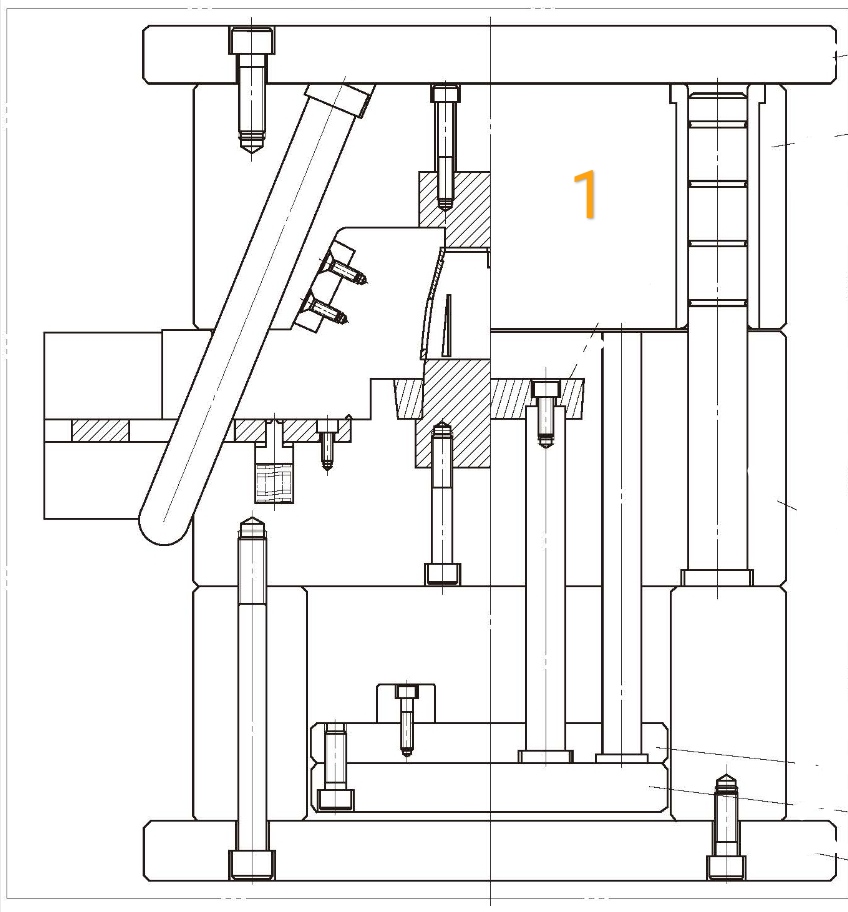

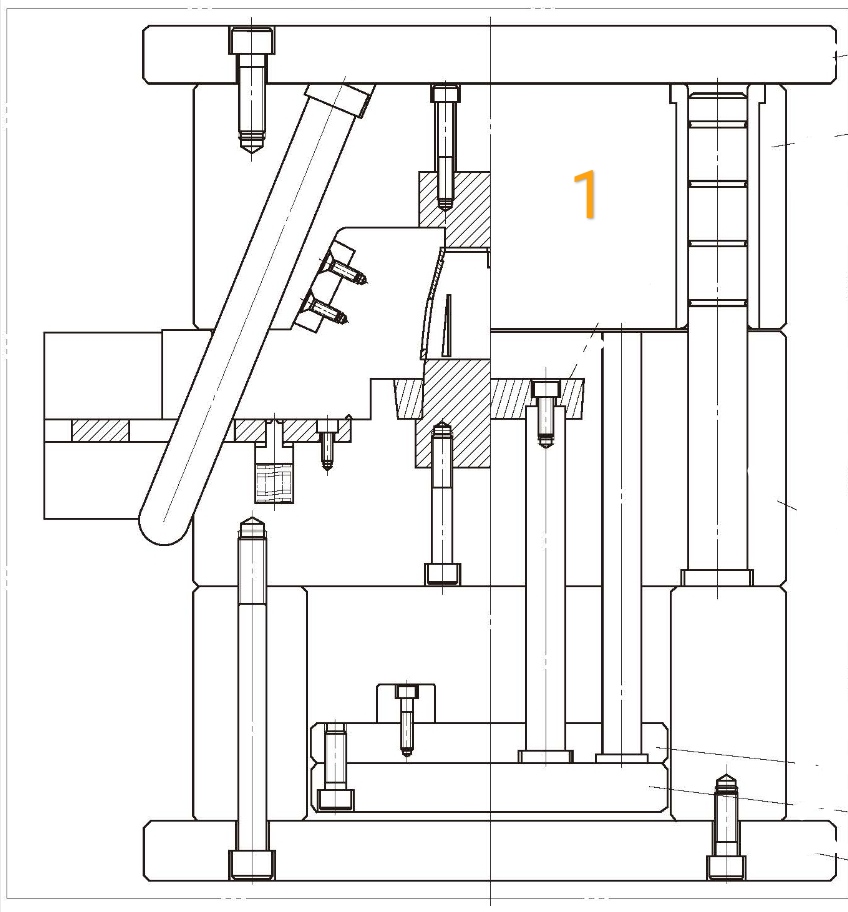

Hiding a stripper plate inside of the mold is to make the stripper plate into a small stripper plate, as shown in figure 1, hiding it inside of plate B, the stripper plate will be locked on the ejector plate, then push the product out through the stripper plate pulled by the ejector plate's ejection. In this way, mold space will be taken as little as possible, it can help reduce the mold size.

This approach is common when the half slider needs a stripper plate to demold. Due to the structural characteristics of the half slider, if you do the whole stripper plate, in order to ensure the strength of the mold, the thickness of the stripper plate is thicker than the slider-free mold, if the stripper plate is designed in the mold, the thickness of the mold can be reduced a lot.

Regarding the same mold, if we made it into a whole stripper plate, slider stroke only needs to be slightly longer than the under-cut, ensure that it can take out the product; if design the small stripper plate inside of the mold, because the slider gives space so that the stripper plate can have enough space to eject, so the slider stroke will be bigger than the stroke of the whole stripper plate.

Design specifications:

1. The slider should be larger than the maximum shape of the stripper plate to ensure that the stripper plate has enough space to eject the product and prevent interference.

2. If the seal off needs to include the stripper plate, need to do a good slope match with the product's insert, if you do not need the seal-off, stripper plate, and insert pieces unilateral gap of 0.2mm or so, should not be too much, to prevent the stripper plate from having a small space to touch the product's surface.

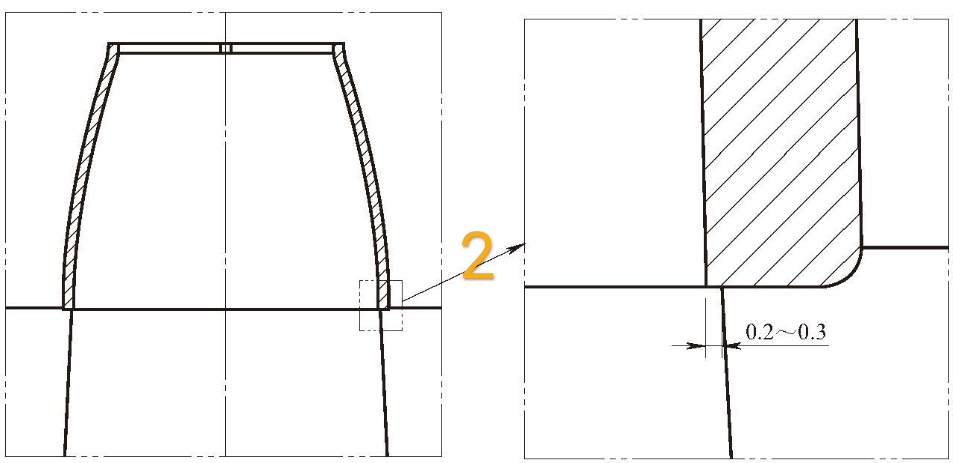

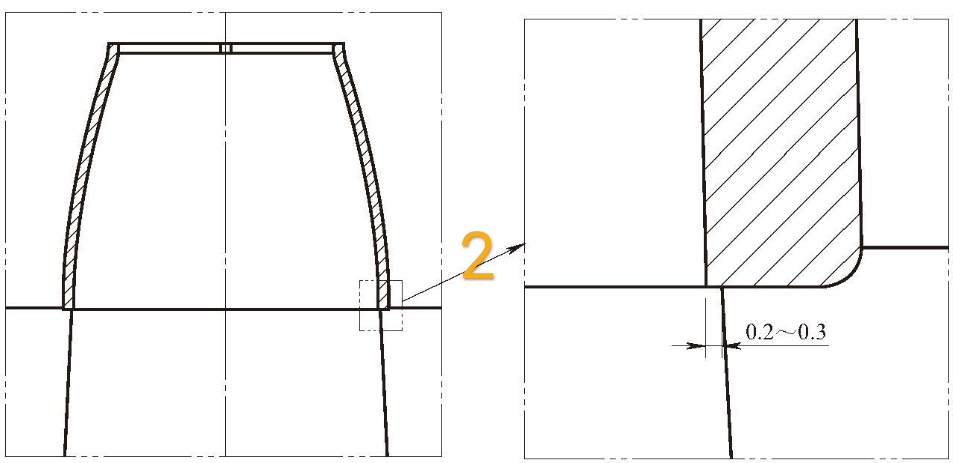

3. All stripper plates to be sealed should be parted at the product location of 0.2 to 0.3mm larger than the inside of the appliance, as shown in figure 2, to prevent the stripper plate scratching insert when ejection.

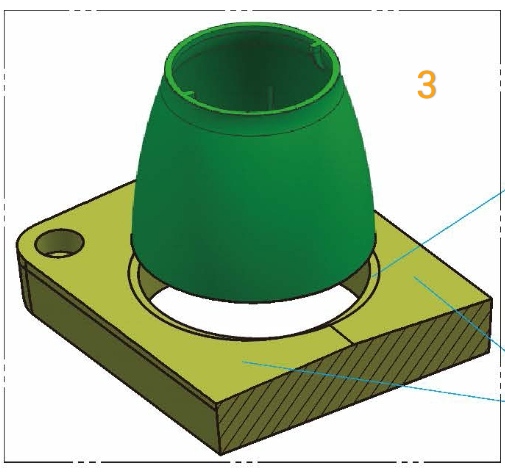

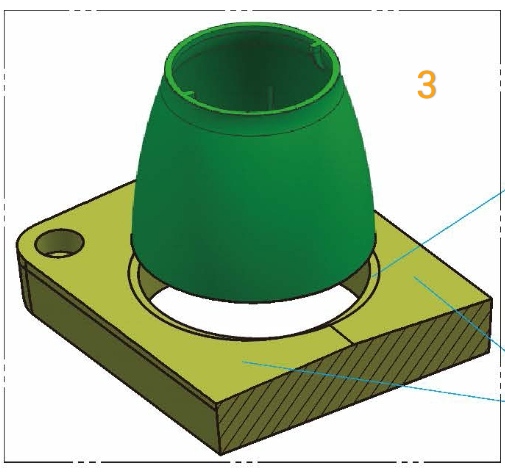

4. To prevent the stripper plate from incompletely returning or the stripper plate from being uneven while clamping mold, causing the slider return's hole to collide with the stripper plate when the slider returns, the top surface of the stripper plate should be sloped, as shown in figure 3.

5. The ejector pin connected to the ejector plate and the stripper plate should sink into the stripper plate to ensure its smooth and stable, non-biased molding, as shown in Figure 1.