Mechanism ejection system's action and parting lock's action is similar, the difference is that mechanism ejection can withstand a larger force, but there is a gap while manufacturing deployment installation, it can not reach the theoretical data value, the different accuracy of the manufacturing affects the quality of the mechanism, when we use it, we usually evaluate its reliability according to the product structure, manufacturing level.

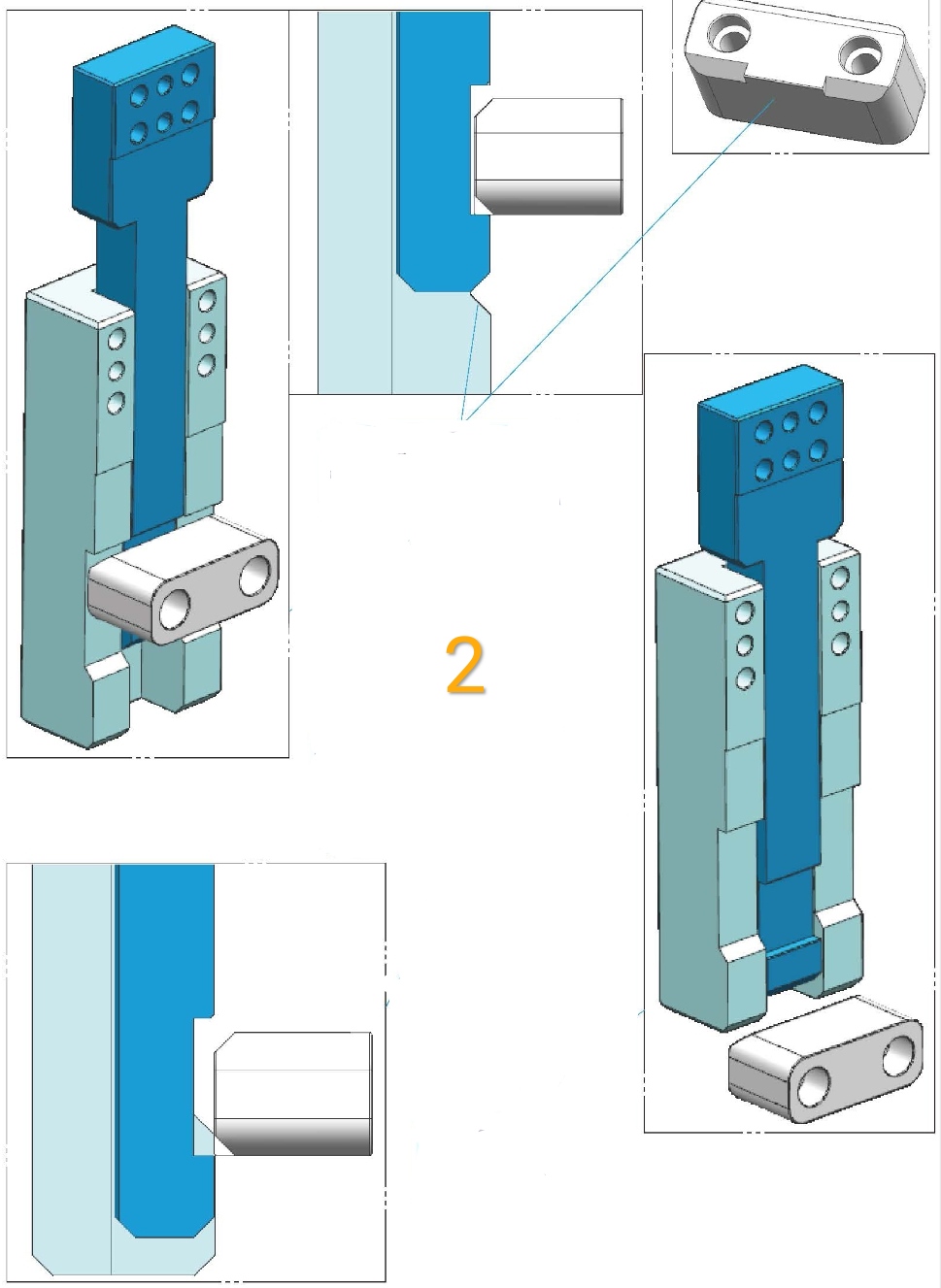

Mechanism ejection system, as shown in figure 1, draw hook is fixed on the cavity's ejector plate, pull block is fixed on the plate A, lever pin is fixed on the plate B, because the lever pin has a spring inside and there is a space inside, so it can stretch freely.

Number 1 stands for draw hook

Number 2 stands for pull block

Number 3 stands for lever pin

Number 4 stands for spring

Letter "S" stands for the stroke

There is a stop stroke between the pull block and the lever pin, and when the pull-block moves to the preset stroke, the pull block moves the lever pin to the end, detaches from the pull block, and completes the action.

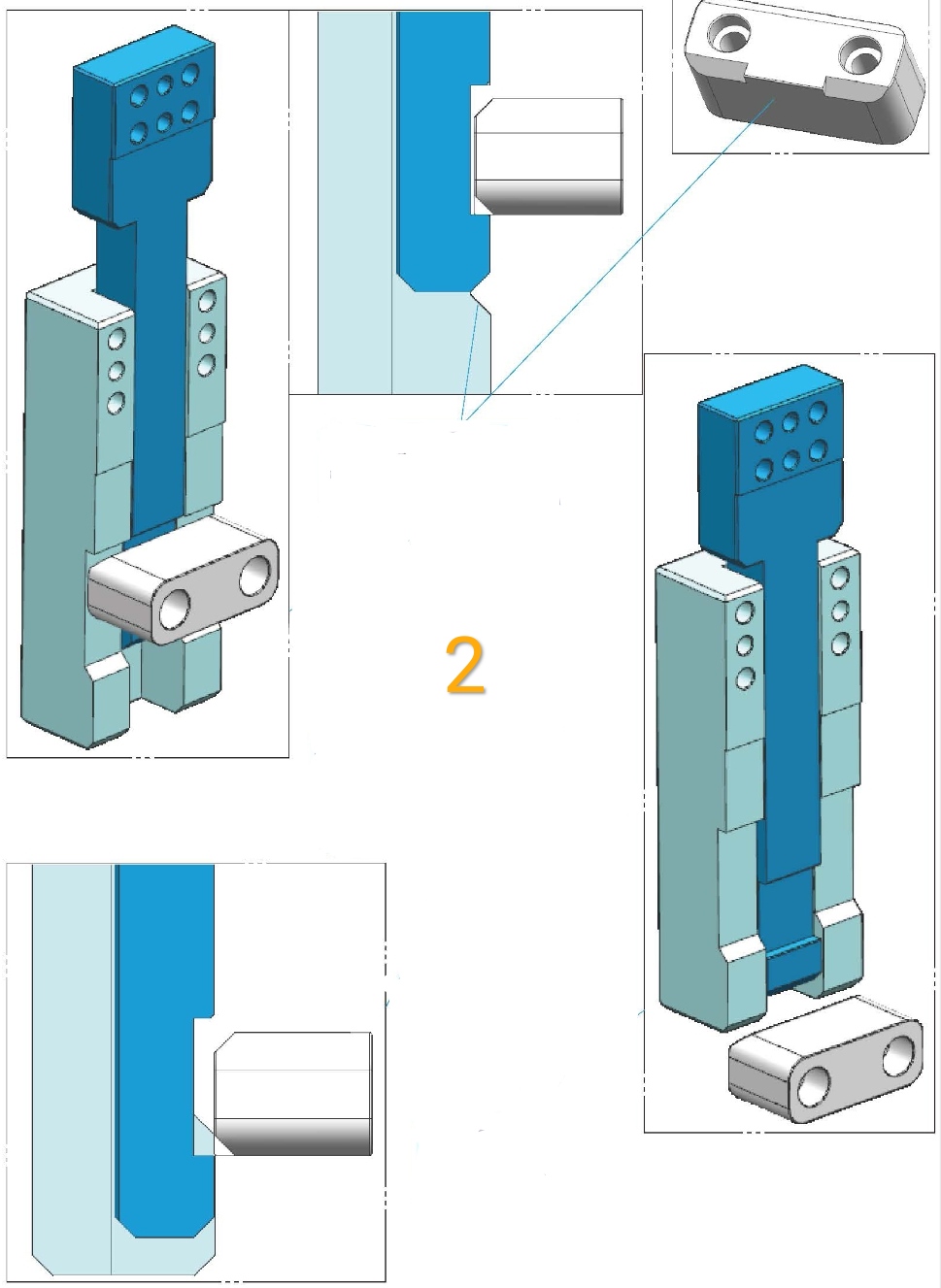

A diagram of the action of the mechanism ejection system shows in figure 2.

Design specifications:

1. The surface of the lever pin and draw hook should be less than the lever pin's stroke so that they can be completely detached.

2. To prevent premature wear, lever pins should use quenching material, and other components can use P20 materials for nitriding.

3. There should have a location between the mold plate and draw hook, pull block to ensure that their motion direction is parallel to the direction of mold opening.

4. The pull block stroke "S" is the same as the ejection stroke of the ejector plate, because the mold ejection stroke has a residual amount, so you don't need to worry about the effect of lever pin and pull block's operation slope on the ejection stroke due to manufacturing or not cooperating correctly.