Inverse injection die can be universally regarded as gating the normal mold via core. What kind of products need to do inverse injection die?

Based on our experience, the products have the below features:

1. The product belongs to surface components, the entire appearance surface is smooth and unobstructed, the product does not allow gate traces.

2. The product size is relatively large, sub-gate and banana gate injection molding is too difficult to guarantee the shot effect. Multiple gating affects the product's quality and so on.

3. When core gating, gat sprue bush is too long, and this type basically uses hot runner gating.

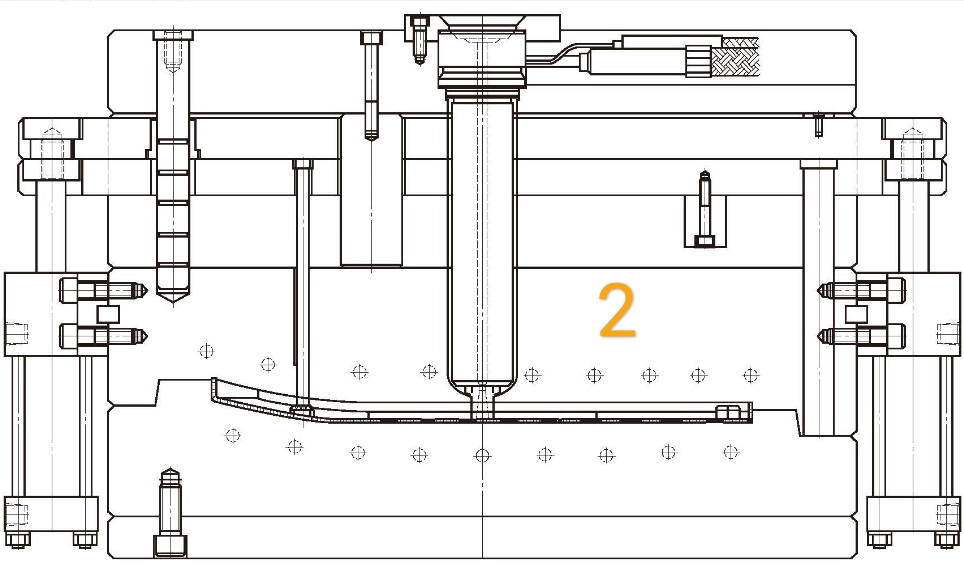

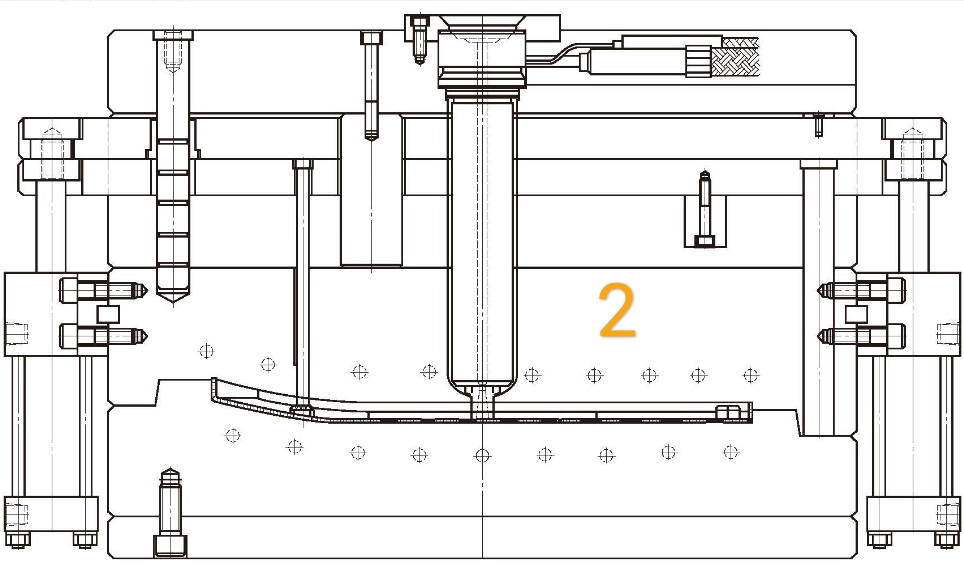

As shown in Figure 1, the product is an appearance component, and it's cavity one, because the entire appearance surface does not allow gating trace, so we consider this product with inverse injection mold.

Design specifications:

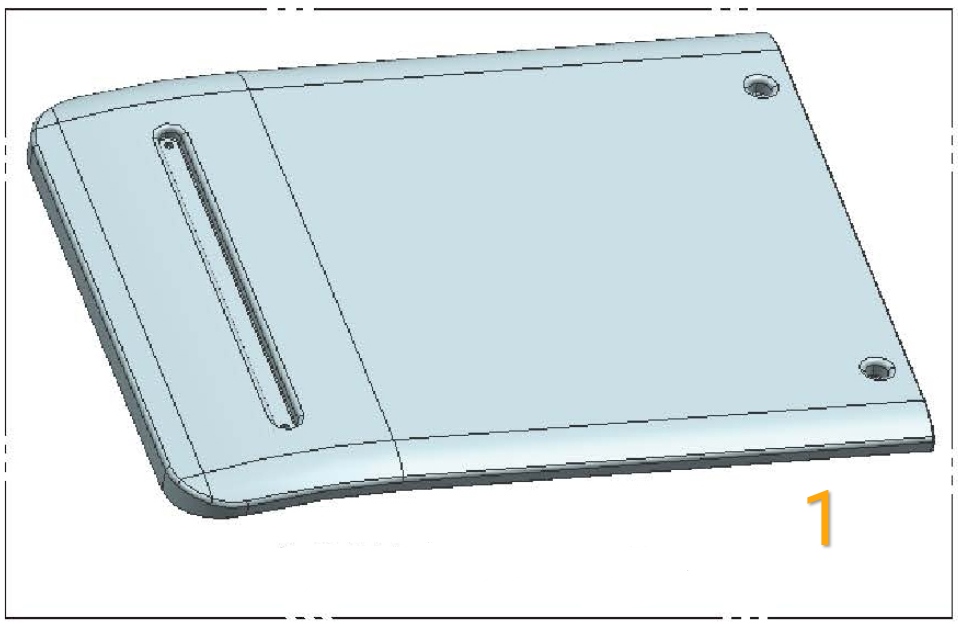

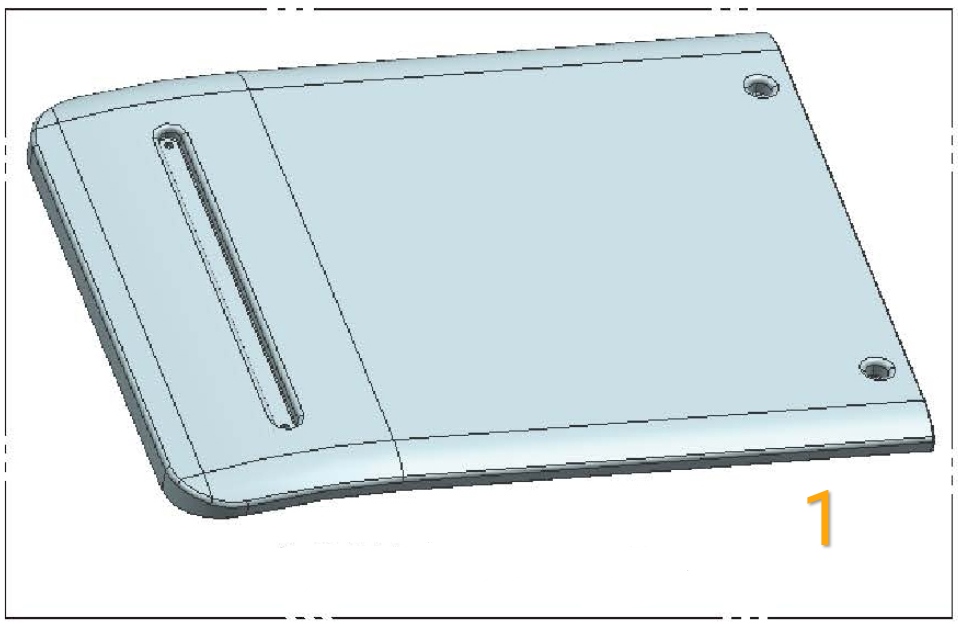

1.When we use inverse injection die, because the size of the gating is too long, resulting in a longer sprue, in order to reduce production costs, we generally use hot runner, as shown in figure 2.

2. Inverse injection molds generally use hydraulic ejection. When the use of hydraulic cylinder mold is prohibited, consider using other systems to pull the ejector retainer plate. When designing hydraulic ejection, be aware of the placement of the hydraulic, make sure to maintain balance on both sides, and ensure that the position of the hydraulic does not affect the manipulator grasping the product.