Before reading the part on how to design the ejection system without an ejector plate, let's see when you can use that special system.

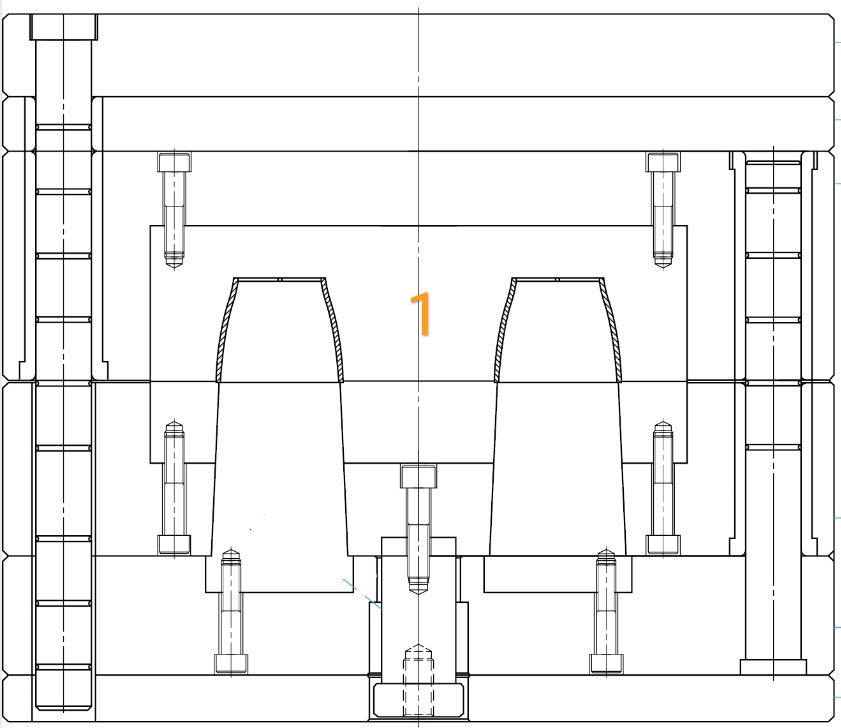

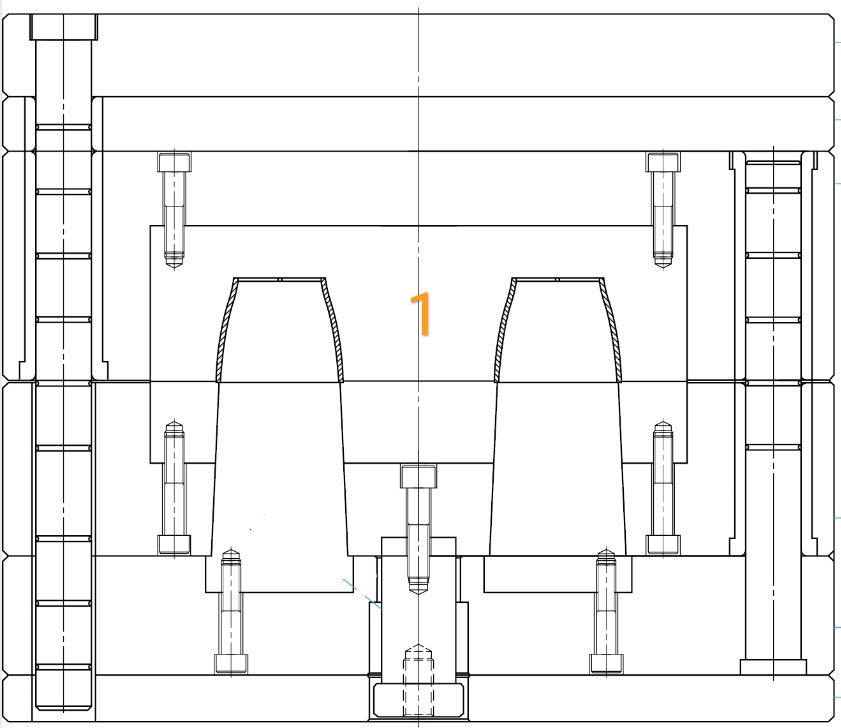

For the complete stripper plate mold, if the mold doesn't have any ejector pin or it only has a sprue pin that won't affect the mold's structure, you can get rid of the ejector plate and spacer block, do a knock-out pin on the stripper plate directly, the knock-out ejects the insert to demold, as shown in figure 1.

Design specifications:

1. You must do the stop location between the stripper plate and plate B, doing a separate stop pin, or doing a step stop location on the knock-out block.

2. Slightly larger molds need to do more than two knock-out holes, you need to pay attention to the position, which can not interfere with the position of the core, if it can be staggered, it is not suitable to use knock-out to actuate ejection, at this time, you should consider another way of ejection actuation.

3. You should do a parting lock pin and fix the parting lock on plate B when you operate on a pin-point gate.