First, you need to know what is the PU and what is the nitrogen spring.

PU is a material between rubber and plastic. It has both the elasticity of rubber and the rigidity of plastic. It can provide greater elasticity, but the compression stroke is shorter. PU is mainly used in the case where a relatively large elastic force is required in the mold, but the stroke does not need to be too long. Check below picture to see it.

Because the PU occupies a small space and has good wear resistance, it provides greater elasticity than the spring. When used as an auxiliary mold opening, the PU is better than the spring.

Application: Vigorously small stroke assisted mold opening, change of mold opening and closing sequence, etc.

Design specification:

Location D is decided according to the size of the mold, there is no mandatory requirement, just moderate.

Location A: 5~10mm

Location B: 20~25mm

Location C: 4~6mm

Let's move to nitrogen spring next.

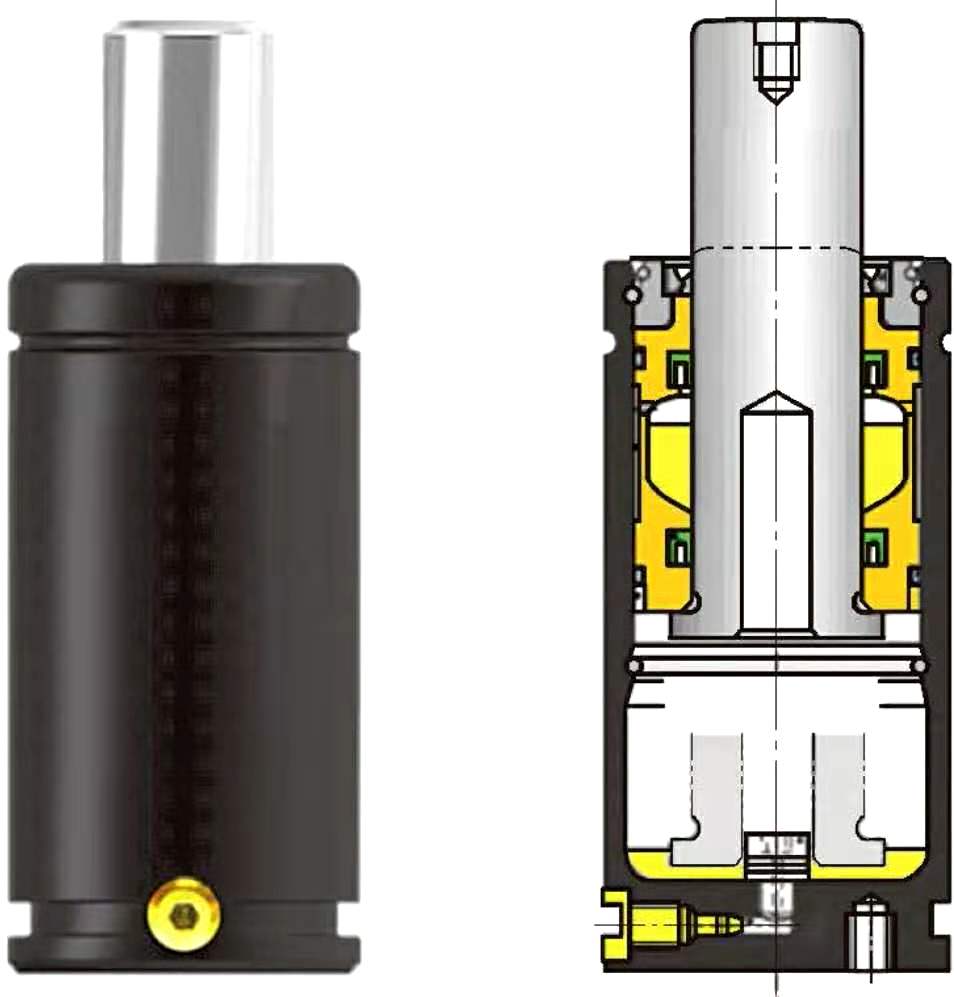

The nitrogen gas spring is currently widely used in the field of molds. It injects high-pressure nitrogen into the cylinder and realizes its function by the movement of the plunger. See below picture.

Nitrogen gas springs have the advantages that metal springs or PU cannot replace in performance. It has the advantages of sufficient elasticity, large formation, good stability, and precision manufacturing. It is often used in the occasions where the elasticity and stroke requirements are relatively large in the mold.

Nitrogen gas springs are mainly divided into ISO international standard type, compact structure, ultra-compact type, and micro-small type. According to the mold structure and space, you can directly select the model you need to use from the information provided by the supplier.

Design specification:

1. The nitrogen gas spring must be fixed on the mold. There are many ways to fix it. For details, please refer to the information provided by the supplier.

2. The contact surface on the top of the plunger should fit the template completely, and it should not be free to return to its position, otherwise it is very easy to damage. Therefore, the nitrogen gas spring must be pre-compressed when it works to the limit, 3~5mm is enough.

3. The nitrogen spring cannot be biased, and the verticality during operation cannot be greater than 0.15 degree. The parallelism between the movement direction of the nitrogen spring plunger and the opening direction should be ensured, and the inclination of the mold itself or the inclination of the mounting surface should also be paid attention to.

4. The normal working temperature of nitrogen gas spring is 0~80℃, exceeding this temperature will affect the service life.

5. The longer the stroke, the larger the diameter, and the more expensive. Therefore, we generally choose the model that is closest to the required stroke.