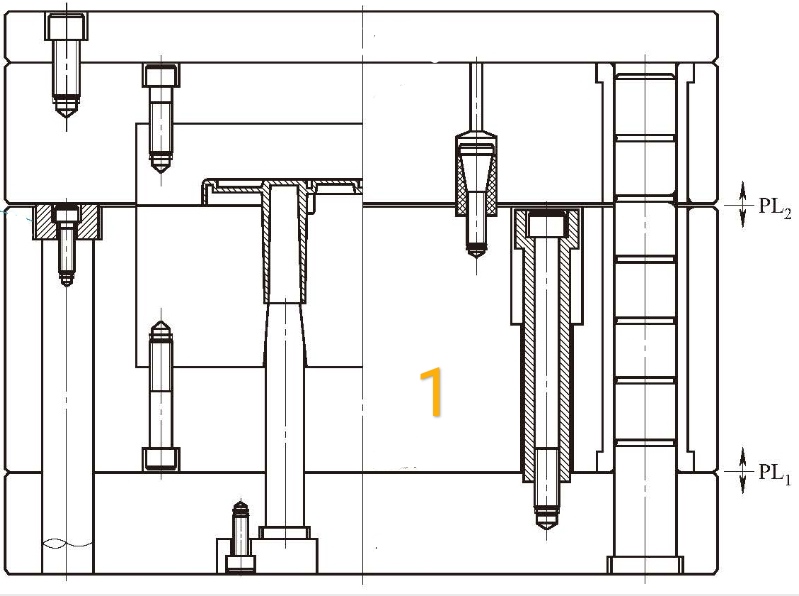

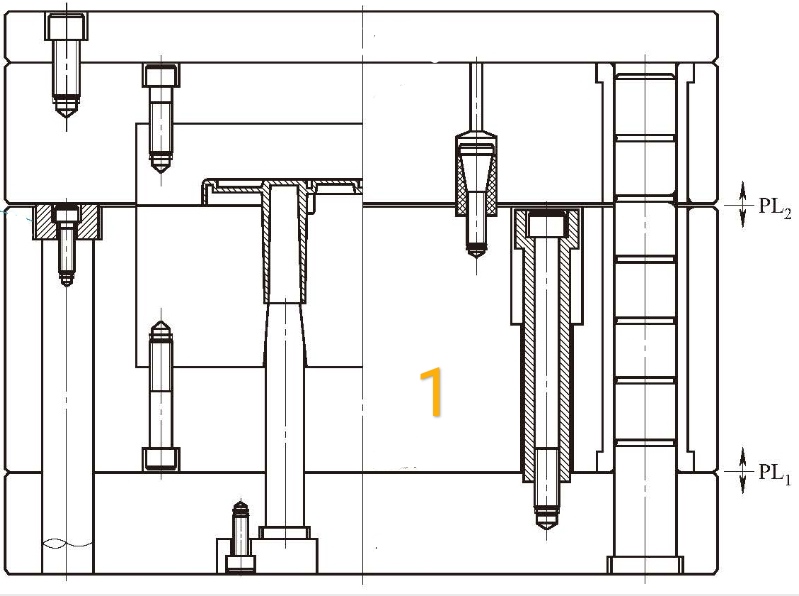

Synchronous core pulling by the cavity structure utilizes the step of opening mold to let the stripper plate move along with the cavity synchronously, before opening plate A, plate B, allow the insert to be pulled out from the product, as shown in figure 1.

Notice:

1. The return pin must be with the block while the ejector plate is moving with the stripper plate synchronously.

2. Regarding the structure of the stripper plate moves along with the cavity synchronously, it's only suitable for the products without sticking the cavity. If priority core-pulling causes a sticking cavity, the stripper plate will fail to move along with the cavity synchronously.

Design specifications:

1. It must have a stop block between the stripper plate and plate B, the stop stroke is equal to the priority pulling distance.

2. As there's a parting lock between plate A and the stripper plate, we need to open PL1 first then move to PL2 while opening a mold, if the PL2 is strong and quickly pulled, the stripper plate bounces back and we can add spring between the plate B and the stripper plate.

3. If the priority insert-pulling molding area is relatively small, it can be inserted on the plate B, using the way from the back cover plate to fix, as shown in figure 1, if the molding area is relatively large, you must dig the pocket from the front of the plate B, taking the same as inserting the core into mold frame.

4. If the ejector plate needs to move along with the stripper plate synchronously, putting a block on the return pin directly, if not, design the return pin as normal mold, as shown in figure 1.

5. The force point of the spring of the ejector pin should be acting on the stripper plate through the plate B, otherwise, the spring and the parting lock will be counterproductive. When the parting lock is detached, the spring pulls back the stripper plate, if the length of the spring is not enough, the pads can be added to the top of the spring.