If there is an equally deep rib in the deeper rib, if we only pulled the outer rib, the rib inside may be taken out along with the insert, causing the product to blush or scuff.

Twice core-pulling is to pull out the deep rib part of the inside of the product, then the outer part, and finally open the mold.

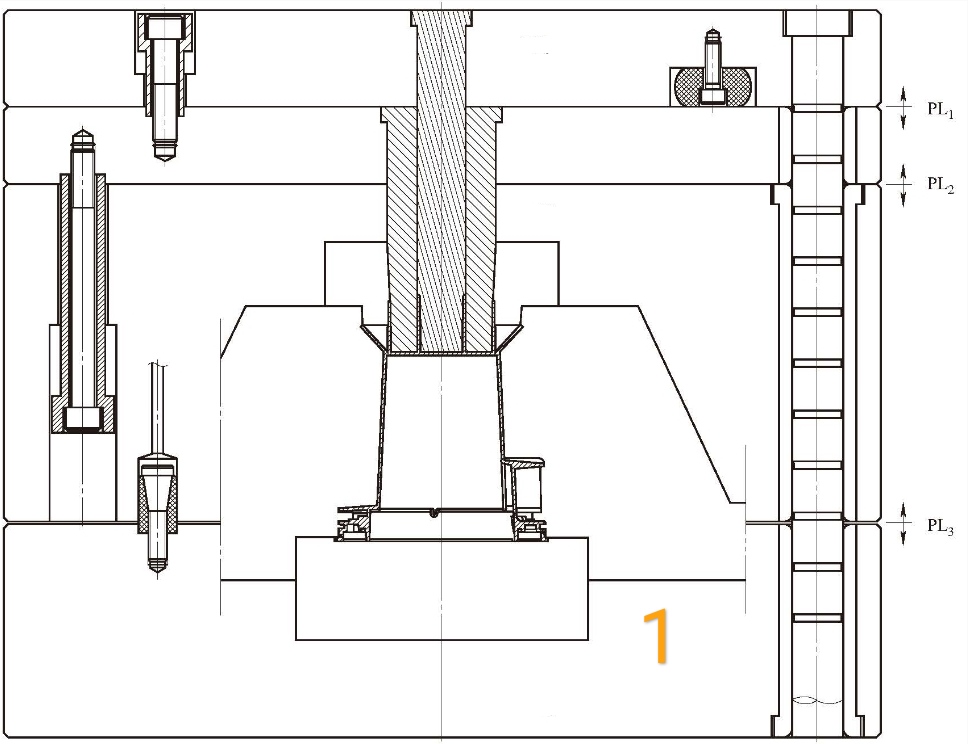

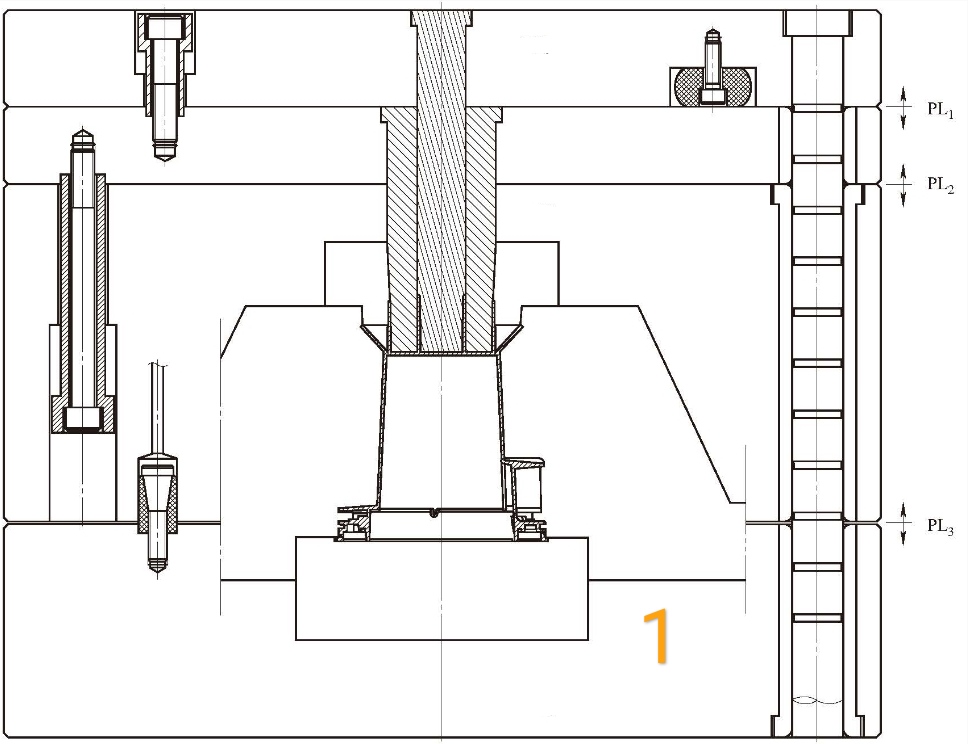

As shown in figure 1, in the front mold of the deep ribs inside there is a deeper rib, if we only take out the outer insert, then the deep rib inside will be scuffed, so we need to first pull out the ring of ribs inside, and then cramp a ring of ribs outside.

Design specifications:

1. Open PL1 first, then open PL2, last, open PL3.

2. To ensure that the mold is opened first at the PL1, add a PU or spring-assisted opening between the top clamp plate and the priority core-pulling plate.

3. Must do a stop block between the top clamp plate and the priority core-pulling plate, the stop stroke is equal to the distance of priority core-pulling.

4.It's mandatory to do a stop block between plate A and the priority core-pulling plate, the position of PL 2 will be pulled through the stop pin.

5. Notice the length of the guide pin, after all of the plates are opened, make sure that the guide pin will insert plate B first while shutoff.