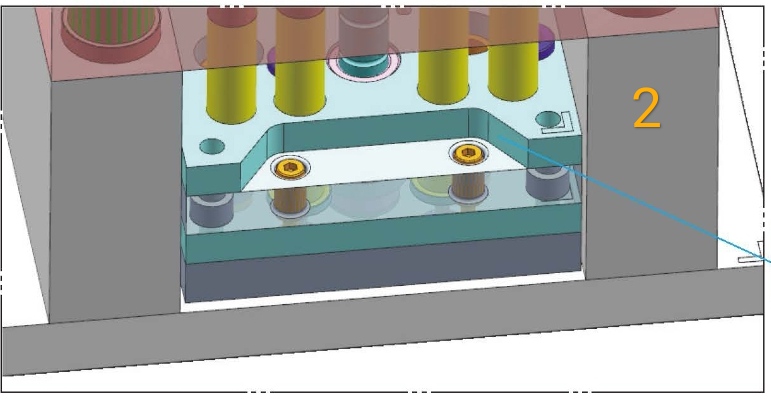

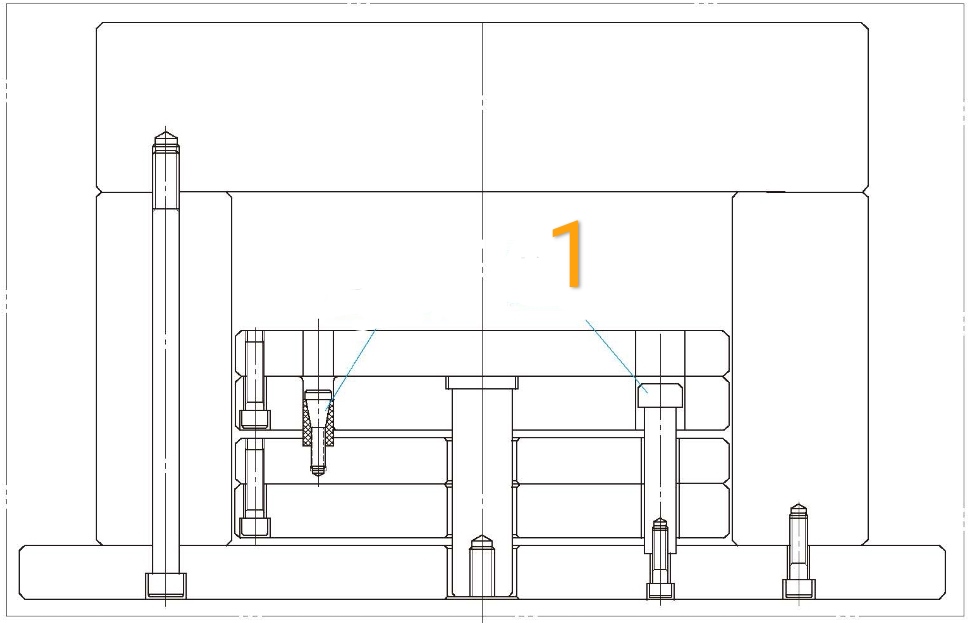

The twice ejection by parting lock utilizes the combination of the parting lock and stop stick, the structure of the twice ejection is completed, as shown in figure 1.

The principle of action:

1. Knockout drives the upper group of ejector plate, with the resin parting lock, the upper group of the ejector plate drives the lower group of the ejector plate synchronous motion, when the movement to the preset position, stop stick pulls down the lower group's ejector plate, the upper ejector plate continues to move, two groups of the ejector plate separate, complete twice ejection.

2. Before the die is closed, it pulls back forcibly to drive the upper ejector plate return, moving to a certain distance, the upper ejector plate drives the lower ejector plate return together.

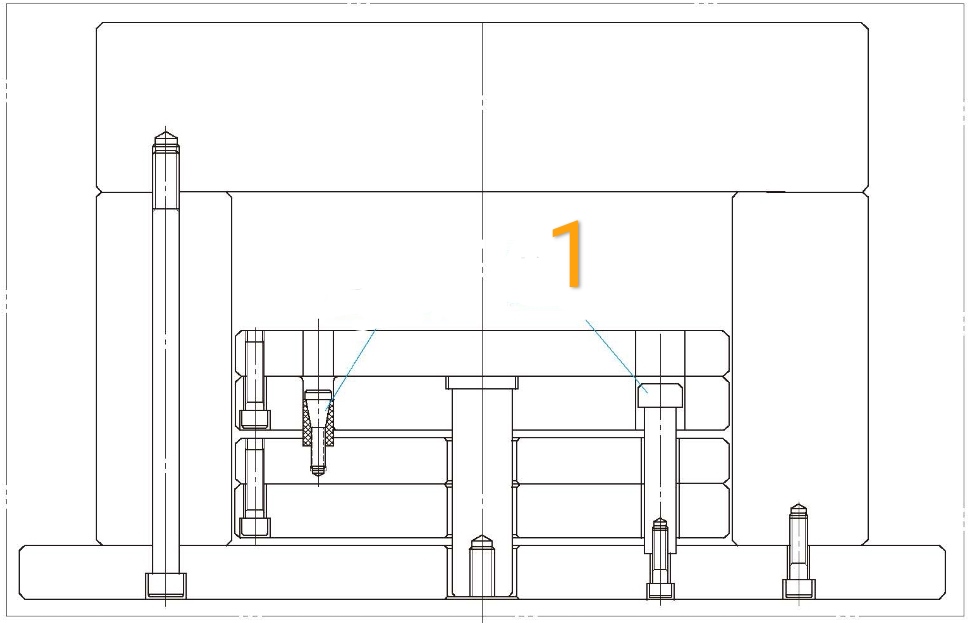

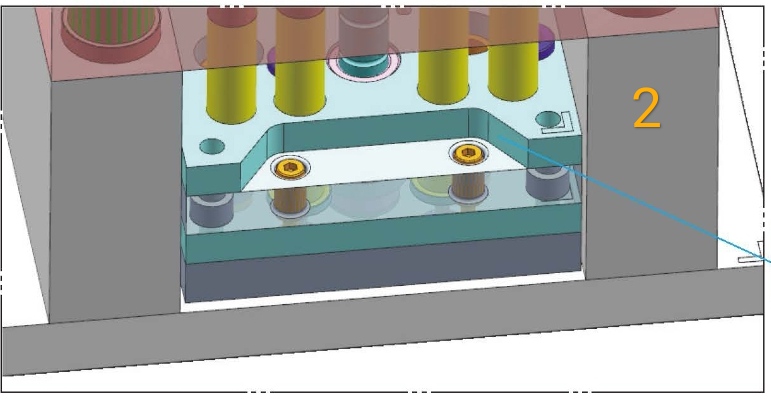

Design specifications:

1. This structure should do two groups of ejector plate, for having an easy adjustment, the parting lock should be installed on the lower group of the ejector plate, as far aside as possible, the upper ejector plate should have the relief hole, as shown in Figure 2, to ensure that there is enough space to adjust the parting lock.

2. This method is mostly used on small molds, large molds are not recommended to do, also the parting lock safety rate is not high as we think.